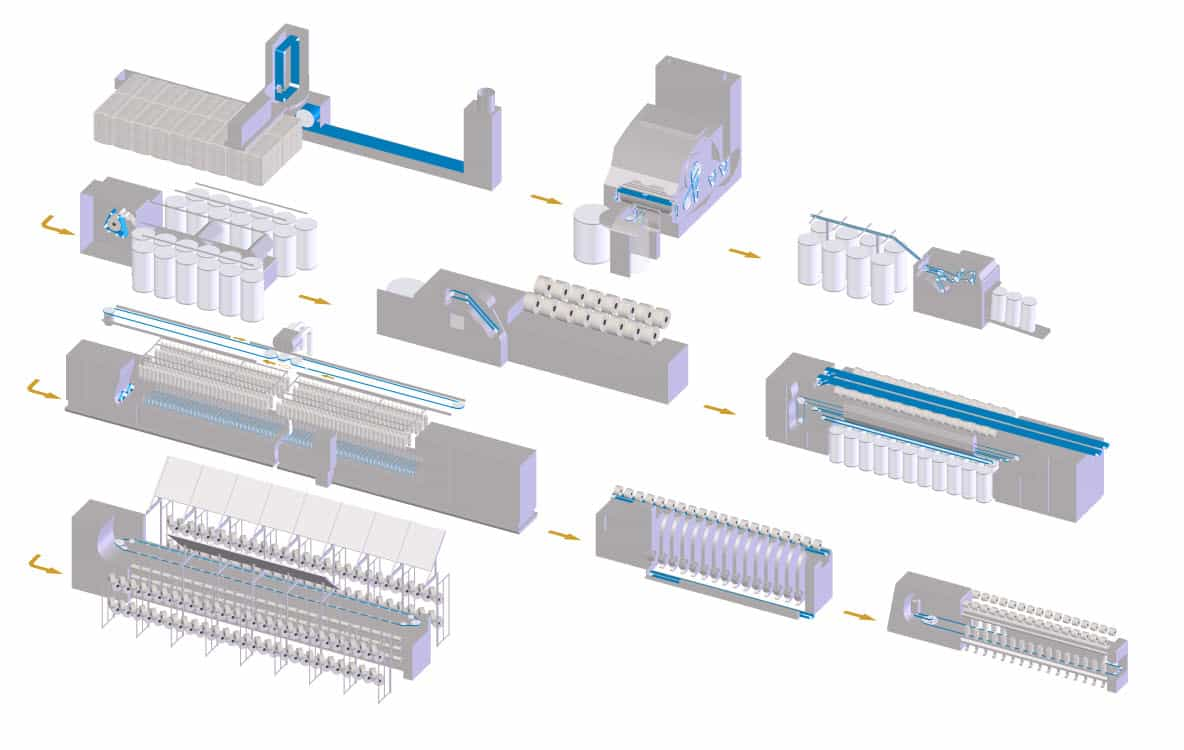

Yarn Spinning, Twisting and Finishing

Fibre preparation, yarn-spinning, twisting, winding and finishing are demanding processes that require high-quality Tangential Belts.

We offer a complete range of RAPPLON® High Performance Flat Belts for the Textile Industry. These products satisfy the ever increasing needs and provide extended service life as well as improved chemical and aging resistance.

Non-woven, Dyeing, Printing and Drying

Refinement processes such as dyeing and printing require smooth and reliable belting solutions.

Ammeraal Beltech’s process and conveyor belts provide an efficient flow of bales, fibres, bobbins and packages. Whether it’s for plane or spike lattice conveyors, blower rooms, aprons, spinning machines or high-speed cross lappers, we’ve got the right belt.

Main challenges

- Quality of finished product

- Tearing of the web

- Belt weight

Solutions

Printing Blankets

Flat bed, rotary, digital or table – our AmPrint range handles every printing system!

Offering extended lifetime thanks to their non-fray construction design and outstanding chemical resistance, our printing blankets are tailored to meet the process requirements for textile printing across the entire spectrum of printing technologies.

Main challenges

- Minimal downtime

- Balanced construction & belt uniformity

- Printing result

- Curling edges

- Chemical resistance to solvents & delamination protection

- Fraying & blanket elongation

Solutions

Our Roll Coverings

Some examples of our materials, available in either self-adhesive or non-stick format.

Features of the roll covering range:

- Abrasion-resistant

- Anti-static

- Oil and grease resistant

- Varying degrees of hardness for both high and low grip

- Narrow tolerances

- Many colours and profiles available

- Available in self-adhesive format

Offering extended lifetime thanks to their non-fray construction design and outstanding chemical resistance, our printing blankets are tailored to meet the process requirements for textile printing across the entire spectrum of printing technologies.

Main challenges

- Minimal downtime

- Balanced construction & belt uniformity

- Printing result

- Curling edges

- Chemical resistance to solvents & delamination protection

- Fraying & blanket elongation

Solutions